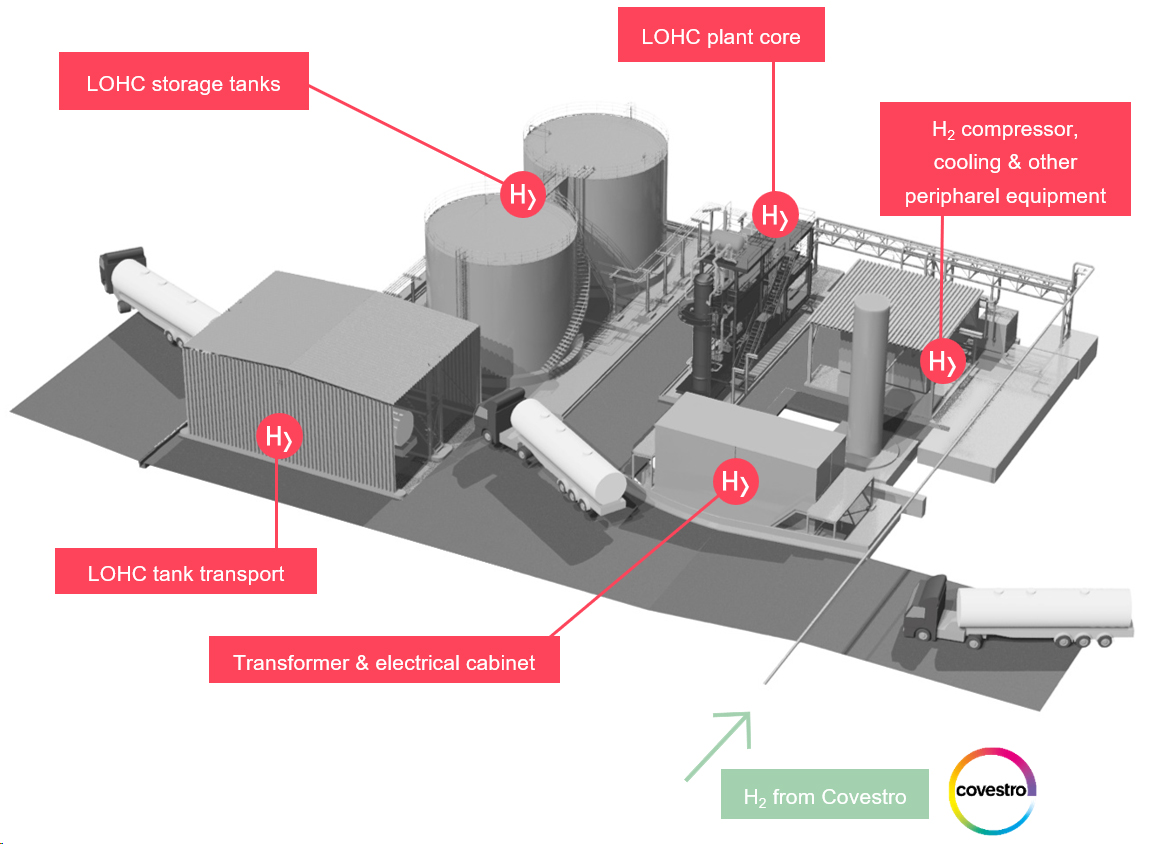

World‘s largest LOHC storage plant

Project Hector represents a significant leap forward in green hydrogen storage and transport. Located at the CHEMPARK Dormagen in Cologne, it is set to become the world’s largest facility for storing RFNBO (Renewable Fuels of Non-Biological Origin) hydrogen using Liquid Organic Hydrogen Carrier (LOHC) technology. Thanks to 9 million Euro in funding from North Rhine-Westphalia’s progres.nrw program, we will be able to store up to 1,800 tons of clean hydrogen annually, pushing the boundaries of hydrogen logistics and creating a blueprint for sustainable energy storage on a global scale. While Hydrogenious LOHC Technologies will contribute the scaled plant system and its key elements, LOHC Industrial Solutions NRW will take charge of project management and plant operations.

Commissioning

End of 2027

Hydrogen storage capacity

1,800t per year

LOHC load per year

40,000 cbm

The project in Dormagen is another important step in the implementation of our Hydrogen Roadmap North Rhine-Westphalia. It is an excellent example of how we can provide our business and industrial location with green hydrogen in the future. It also forms the nucleus for the creation of new, future-oriented jobs and supports the Rhenish Revier in becoming the leading hydrogen location. We see this innovative technology as a crucial component for a sustainable hydrogen economy that builds on existing structures in the region

Industrial-scale hydrogen storage in LOHC

We are proud to work alongside Covestro Deutschland AG, a leader in sustanaible hydrogen production. Covestro, which has been a shareholder in Hydrogenious LOHC Technologies since 2019, will provide RFNBO-Compliant hydrogen for the facility, produced as a by-product from their own industrial processes. One focus of the project is to integrate the heat energy released during the LOHC hydrogenation process into the steam network and thus into the site’s energy supply. By utilizing this waste heat, we are able to enhance the overall efficiency of the LOHC cycle and lower the levelized cost of hydrogen. This highlights how seamlessly LOHC technology can integrate into existing industrial ecosystems, creating synergies that benefit both energy producers and offtakers.

Clean hydrogen supply for LOHC Link

In the future project Hector will be connectected to IPCEI Green Hydrogen @ Blue Danube to supply industrial offtakers in Southern Bavaria. This will create a comprehensive and resilient climate-neutral hydrogen supply chain based on LOHC that serves as perfect blue print for enabling remote areas with no pipeline or port infrastructure with access to clean hydrogen. This unified, comprehensive clean hydrogen supply chain project is called LOHC Link.

Our commitment to innovation extends beyond just technology. As part of project Hector, we are working closely with the Jülich Research Centre, which will lead the accompanying scientific research. This will focus on optimizing catalyst performance, ensuring the quality of both hydrogen and LOHC materials, and developing robust quality assurance processes for industrial-scale applications. By tackling these scientific challenges head-on, we are setting new standards for hydrogen storage systems globally

Project & funding partners

Covestro is one of the world’s leading manufacturers of high-quality plastics and their components. As part of Project Hector, Covestro supplies RFNBO hydrogen, which is produced ub their chlorine electrolysis plant.

The scientific partner of project Hector is the Jülich Research Centre with its Institute for Energy and Climate Research. Two million euros of the funding for accompanying scientific studies will go there.

The Ministry of Economic Affairs, Industry, Climate Protection and Energy of North Rhine-Westphalia is supporting project Hector with nine million euros from the “progres.nrw Innovation” program.

Press Release

Kick-off for construction and operation of the world’s largest plant for storing green hydrogen in Liquid Organic Hydrogen Carrier

Press Release

State government supports development of a globally unique storage and transport technology for hydrogen with nine million euros

Media

Get the latest plant visualization renderings and concept drawings of project Hector here (© Hydrogenious LOHC Technologies)

Project Hector