We store hydrogen in a liquid organic carrier. The missing link to clean hydrogen supply chains.

Our LOHC Technology – disrupting hydrogen infrastructure

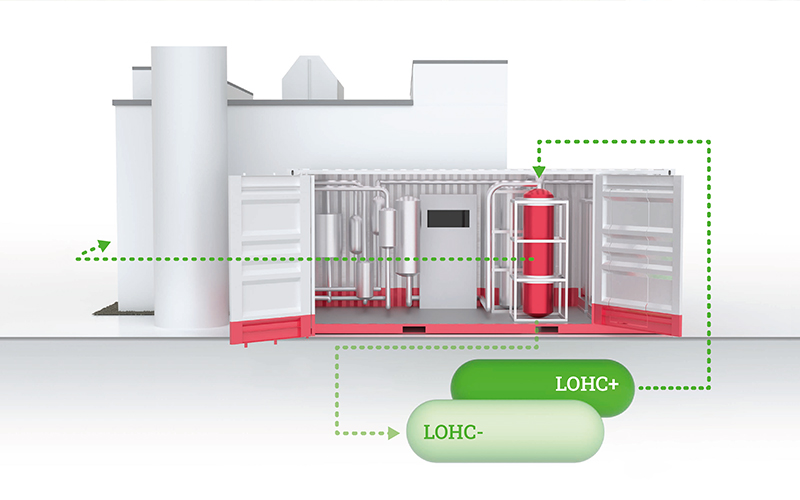

The LOHC Cycle

Hydrogen is the most abundant element in the universe and can be produced using renewable energy sources. At the same time, it has the lowest density of all gases and has nearly three times the energy content compared to gasoline. Long story short: Hydrogen is the best energy carrier known to mankind. But it is difficult to handle. Good news is, we found a way to bind the molecular hydrogen to a thermal oil making it very safe and very easy to transport – this is our LOHC technology.

High efficiency

- Competitive volumetric storage density 54 kg hydrogen per m³ LOHC

- Carrier material commercially available and reusable hundreds of times

- Fuel cell grade hydrogen purity according to ISO 14687 by using off-the-shelf purification technology

Enhanced flexibility

- Conventional liquid fuel infrastructure usable

- Handling at ambient temperatures and pressure during storage and transport

- No self-discharge over time – multi-month storage without losses

Superior safety

- No handling of molecular hydrogen

- Hardly flammable with flash point 112,5 °C, non-explosive, even when loaded with hydrogen

- Hazard potential comparable to Diesel and thus clearly superior to ammonia

Key stepping stones for ramping up the LOHC ecosystem

Green Hydrogen @ Blue Danube

IPCEI Green Hydrogen @ Blue Danube will be the first LOHC hub in Central Europe with a hydrogen release capacity of up to 1,800 tonnes per year. This hub will supply industrial offtakers in the Danube region and beyond by 2028.

Hector

Located at the CHEMPARK Dormagen, Project Hector is set to become the world’s largest facility for storing green hydrogen using LOHC technology. Together with Green Hydrogen at Blue Danube it will form a comprehensive LOHC value chain at industrial-scale.

One Reactor

In Project One Reactor we aim to unlock the full potential of LOHC as an energy storage medium. At the center of the project is a medium-scale facility with a hydrogen storage and release capacity of approximately up to 300 kg per day.

Demo Project Multi-SOFC

In collaboration with several strategic partners, we are deploying hydrogen-based energy for Hermann Josef Hospital (HJK) in Germany. This showcase project brings together our LOHC technology and Bosch’s Solid Oxide Fuel Cells (SOFC).

H2A-RP

In the joint cross-border lighthouse project H2A-RP, we are driving the installation of one of Europe’s first industrial large-scale LOHC Release Plants. We are enabling the import of 36,000 tonnes of green hydrogen per year through LOHC technology.

H2Sektor

At the hydrogen refuelling station Erlangen we have established a complete LOHC supply chain with green hydrogen as a fuel for mobility. This demo project ranging from hydrogen production to end use shows the majurity of LOHC technology.

TransHyDE Helgoland

The TransHyDE Helgoland project explores and develops a model transport chain based on LOHC technology between the island of Heligoland and the Port of Hamburg. The project also investigates the use of waste heat from the hydrogenation process for heating the island, addressing material and safety aspects, classification, and standardization.

Leading science and research advancing LOHC tech

-

Friedrich-Alexander-Universität Erlangen-Nürnberg

Founded in 1743, Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) is now one of the largest research universities in Germany with about 38,000 students. One of the key research priorities of FAU is the subject area “energy, environment and climate”. In this field scientists are developing an interdisciplinary approach to producing renewable energy with printable photovoltaic technology, conversion into chemical energy using electrolysis and fuel cells – and scalable storage in LOHC. As a spin-off from FAU, Hydrogenious maintains a very close partnership when it comes to basic research. Even today FAU professors a part of Hydrogenious’ scientific advisory board.

-

Helmholtz Institute Erlangen-Nürnberg for Renewable Energy

The Helmholtz Institute Erlangen-Nürnberg for Renewable Energy (HI ERN) investigates and develops material- and process-based solutions for a climate-neutral, sustainable, and cost-effective utilization of renewable energies. The institute works on the structural and functional characterization, modeling, and processing of materials relevant to hydrogen and solar technology. The common goal is the understanding of structure-performance-process relationship on the mesoscale. The “Chemical Hydrogen Storage” research department of HI ERN targets new chemical hydrogen storage technologies such as LOHC, related catalytic processes and material technologies. The HI ERN is set up as part of Forschungszentrum Jülich and is operated in close cooperation with Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) and Helmholtz-Zentrum Berlin (HZB).

-

Forschungszentrum Jülich

The Institute for a Sustainable Hydrogen Economy (INW) of Forschungszentrum Jülich will pool the scientific activities in this field within the H2 innovation centre of the Helmholtz hydrogen cluster HC-H2, where Forschungszentrum Jülich will bring its broad expertise with hydrogen to bear and connect with partners. Research at INW will focus on chemical hydrogen storage technologies using liquid and easily liquefiable hydrogen carriers that can be handled in a similar way to conventional fossil fuels. Research at INW will be conducted in at least four research fields, ranging from the nano- to the mesoscale and from the reactor to the system scale.

Pioneering bio-based hydrogen carriers

While our LOHC benzyltoluene originates from fossil sources, it stands out as a clean, future-ready energy carrier thanks to its closed-loop cycle with minimal material loss. To take sustainability even further, we are pioneering the development of bio-based LOHCs made from lignin – a natural and renewable polymer found in the cell walls of plants.

This research is part of the EPOCH project, a consortium of seven partners backed by the European Commission’s Horizon Europe fund. A key focus of EPOCH is the production and direct electrocatalytic loading of biological LOHCs from lignin. As a global leader in LOHC technology, we proudly contribute our techno-economic expertise to help transform this breakthrough from lab-scale research into real-world impact.

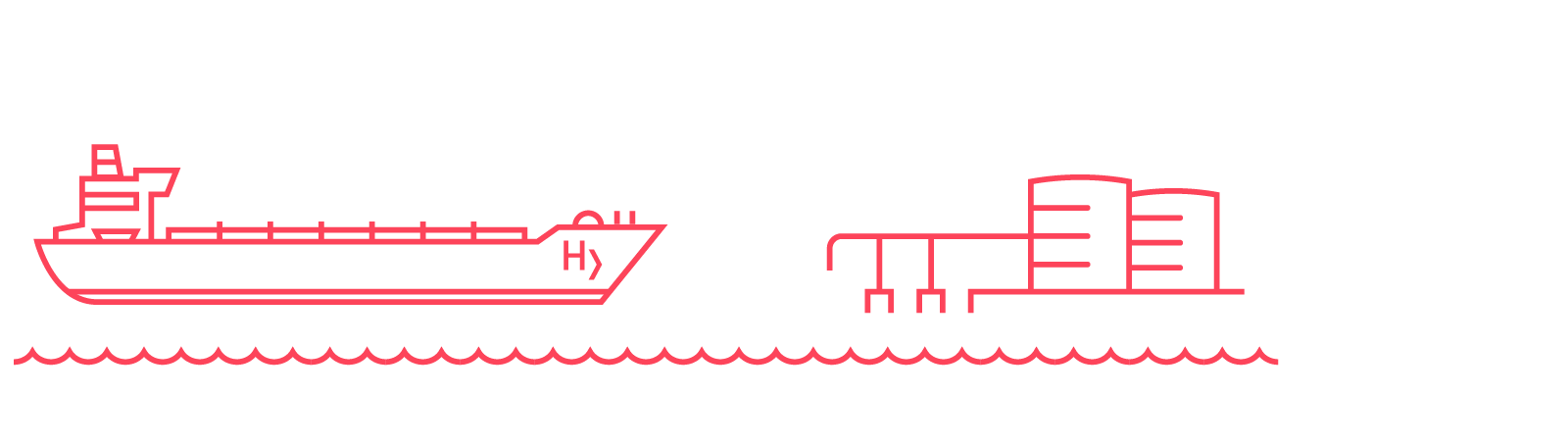

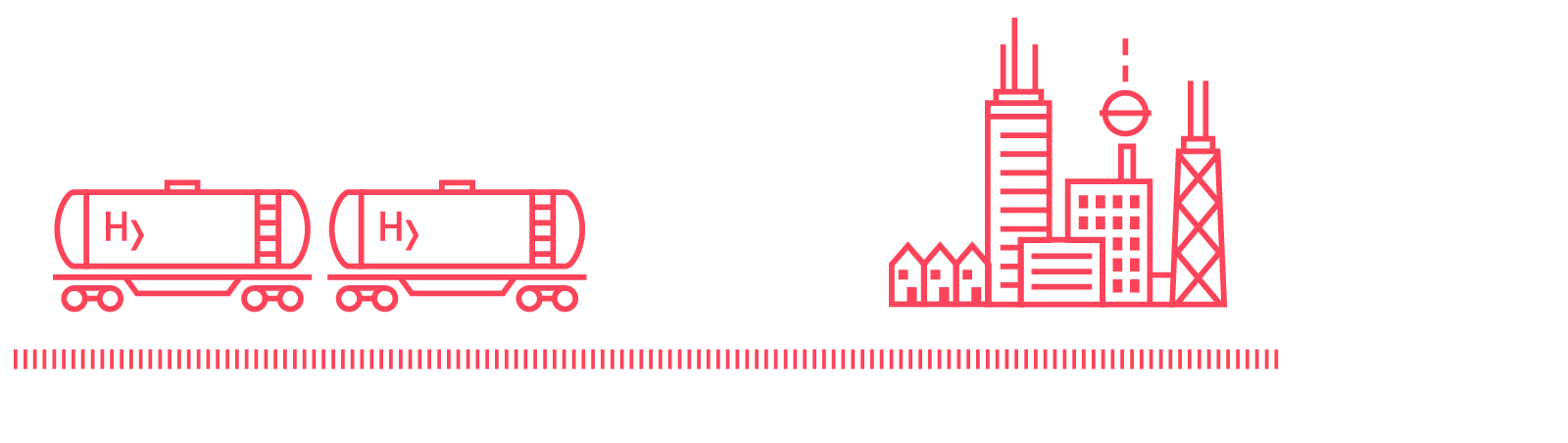

Easy and efficient: We utilize conventional liquid-fuel infrastructure

We are about creating global LOHC supply chains for green hydrogen from production facilities to worldwide consumption markets. This LOHC network is designed to transport green hydrogen very safely and efficiently to the offtakers using the existing infrastructure for fossil fuels. In this network we are developing logistic solutions for all LOHC transport modes with the goal to establish multi-channel deliveries. Currently our focus is to establish a large-scale port to port LOHC infrastructure from where onward distribution is possible.

With similar but much less dangerous transport conditions than diesel, our LOHC material – benzyltoluene – has the potential to replace the current liquids in the energy sector: Bound to LOHC, hydrogen is stored at ambient conditions without the need of pressurized or cryogenic vessels. Plus, benzyltoluene is flame retardant, non-explosive and has a relatively low hazard potential.

LOHC transport

by ship

- Hydrogen transport capacity per trip: approx. 17,000 t (VLCC, 280k DWT)

- Ideal for large scale hydrogen transport on long distances

- Import of low-cost green hydrogen to consumption markets

- Low CAPEX thanks to the usage of the existing infrastructure

- Easy and fast handling by pumping a liquid

by train & barge

- Hydrogen transport capacity per trip: up to 124 t

- Ideal for transport on medium distances and distribution

- Usage of the existing port, ship, rail and train infrastructure

- Highly flexible distribution enabling global market supply

- Easy and fast handling by pumping a liquid

by tank truck

- Hydrogen transport capacity per trip: up to 1.6 t

- Ideal for short distances and distribution

- Standard unpressurized aluminium tank

- Connecting isolated regions to the hydrogen world

- Simultaneous receiving and discharging of LOHC (up to 1.000 l/min)

LOHC storage

One of the biggest advantages of LOHC is, that the bound hydrogen can be stored completely loss free over a longer period of time. Hydrogen is only released from the oil when a catalyst is present and at temperatures of about 300 °C. This property makes LOHC ideal for a continuous and flexible supply with hydrogen.

Lorem ipsum dolor …

LOHC in comparison to other technologies

Business Development

Stefan Stollenwerk

Vice President Business Development & SalesLorem ipsum dolor est

-

Quiande esequiduci dolo occum earchic atiatur eperepe lisque?

Quiande esequiduci dolo occum earchic atiatur eperepe lisque? Quiande esequiduci dolo occum earchic atiatur eperepe lisque? Quiande esequiduci dolo occum earchic atiatur eperepe lisque?

-

Quiande esequiduci dolo occum earchic atiatur eperepe lisque?

Quiande esequiduci dolo occum earchic atiatur eperepe lisque? Quiande esequiduci dolo occum earchic atiatur eperepe lisque? Quiande esequiduci dolo occum earchic atiatur eperepe lisque?